Pipeline maintenance & Cleaning

Chemlogic’s pipeline cleaning and maintenance chemistries are based on years of pipeline debris analysis, single application – single product development, and the essential efficacy studies. Of course, when coupled with our customer’s experienced field services, success is imminent. How do we produce successful results?

Chemlogic’s determined technical development personnel will develop a single product “rifle focused” to perform based on numerous proprietary factors. Other suppliers offer mass produced products that commonly slow the cleaning project turnaround, increase the number of pig runs and product use rates, and in the end, benefits only the seller.

Chemlogic evaluates pipeline records, previous pig trap analyses, along with any pigging debris samples that we forensically analyze utilizing various diagnostic analytical procedures to determine what the debris is composed of and how it formed. We then process the data in our comparative pipeline debris database which currently consists of >500 debris analyses. Once cross-referenced, we verify various chemistries for cleaning and dissolution efficacy. We either formulate a new chemistry based on requirements or adjust a current chemistry for increased effectiveness. In doing so, Chemlogic develops your debris analysis report and recommendation for your perusal.

Products

Pipeline Cleaning Technologies

Hydrostatic Testing Water Treatment

EPA Registered Microbiocide

Corrosion Inhibitors for Natural Gas Pipelines

Corrosion Inhibitors for Oil Pipelines

Corrosion Inhibitors for Gasoline and Diesel Fuel

Drag Reducing Agents

Friction Reducing Agents

Hydrogen Sulfide Scavengers

Scale and Debris Inhibitors

Scale Removers; Synthetic Safe Acid

Paraffin and Asphaltene Inhibitors

Paraffin and Asphaltene Solvents/Dispersants

Antifoam Additives

Biodegradable Solvents

Surfactants

Our process

What does our improved process for product development and selection deliver to you?

When Chemlogic is allowed the opportunity to review previous analyses records or reports, we’ll have enough intelligence to focus the precise existing chemistry and have it onsite within hours of the request.

And, if given the opportunity to analyze a debris sample, Chemlogic will either develop a specialty formulation designed specifically for the debris matrix or find the best existing product solution available.

The recommendation and effectiveness reports, as well as the novel chemistry, will be available in 12 – 48 hours for rush shipments.

When you employ a chemistry designed specifically for the debris matrix that will be encountered, you can reduce project turnaround time by up to 50% or greater. Developing or choosing the right product means fewer, and more effective pigging runs. It also produces less waste to dispose of and faster inspection for Federally mandated records.

Correctly cleaned pipelines provide for an improved and speedier ILI run ultimately saving on regulatory expenditures. And, clean pipelines have higher throughput efficiencies, reduced compression issues, easier follow-up maintenance pigging, and ultimately mitigates the likelihood of redeposition.

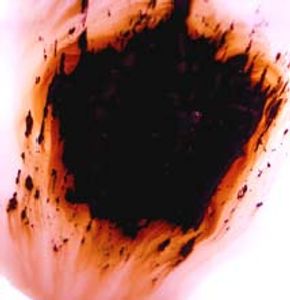

Pyrophoric Iron Sulfide Dissolution

Pyrophoric Iron Sulfide Dissolution

Pyrophoric Iron Sulfide Dissolution

Asphaltene/Paraffin Dissolution

Pyrophoric Iron Sulfide Dissolution

Pyrophoric Iron Sulfide Dissolution

Product information

Chemlogic IL-1400 is a non-aqueous, water-soluble, pipeline cleaning chemistry, designed to dissolve iron sulfide and other iron contaminants, carbonates, and sulfurous compounds. Developed to perform as a broad-spectrum product while testing efficacy on hundreds of pigging debris samples. The proprietary blend of chemistries was formulated to sequestrate, chelate, and disperse debris, while absorbing any free water or moisture in the pipeline. IL-1400 is the ideal choice for cleaning and prepping lines, equipment, filters, drips, lines, and the process system. IL-1400 will effectively solvate the debris compounds that bind iron particles together in an agglomerated mass, thereby allowing debris material to be flushed free of metal substrates leaving an amazingly clean system.

Chemlogic IL-1408 is a non-aqueous, water-soluble, pipeline cleaning chemistry, designed to dissolve iron sulfide and other iron contaminants, carbonates, and sulfurous compounds. The product is the primary choice for pyrophoric iron sulfide contaminated lines. IL-1408 will perform as a broad-spectrum product and can be applied by continuous injection or batched in front of routine pigging runs. The proprietary blend of chemistries was formulated to sequestrate, chelate, and disperse debris, while absorbing any free water or moisture in the pipeline. IL-1408 is the ideal choice for cleaning and prepping lines, equipment, filters, drips, lines, and the process system that are predominantly plagued with the various iron sulfide species.

Chemlogic IL-1410 is a non-aqueous, water-soluble, pipeline cleaning and treatment chemistry, designed to dissolve iron sulfide and other iron contaminants, carbonates, and sulfurous compounds by continuous injection. The chemistry will cleanup gathering, transportation, and downstream systems; including compression units and amine sweetening systems. Developed while testing and effectively treating gathering systems that were contaminating amine sweetening systems. Continuous injection of IL-1410 reduces amine usage, and increased plant efficiencies by dissolving iron sulfide debris. IL-1410 is the ideal choice for continuous injection cleaning of lines, equipment, filters, drips, and the process system. IL-1410 will effectively solvate the debris compounds that bind iron particles together in an agglomerated mass, thereby allowing debris material to be flushed free of metal substrates and easily separated in a supernatant liquid.

Chemlogic IL-1412 is a non-aqueous, water-soluble, pipeline cleaning chemistry, designed for biologically contaminated systems that have high levels sessile biomass. These binding agents combine with iron sulfide and other iron contaminants to cause under-deposit corrosion and plugging debris. IL-1412 will effectively dissolve and remove iron and biomass ontaminants through sequestration, chelation, and dispersion.

Chemlogic IL-1414 is based on the same chemistry composition as IL-1400, except for additional asphaltene and paraffin dispersants. The product was designed for systems with iron, calcium, and sulfurous debris that is heavily coated with either asphaltene or paraffin in the debris matrix. The dispersant package allows quick penetration in the heaviest wax deposits allowing the iron sulfide dissolution chemistry contact with the debris field.

Chemlogic IL-1420 is a unique biomass dispersant designed to penetrate and remove sessile and planktonic infestations in production, gathering, and transportation systems. IL-1420 can be applied by continuous injection or batched into lines on a recommended interval to maintain a clean system.

Chemlogic IL-1422 is a unique biomass dispersant designed to penetrate and remove sessile and planktonic infestations in production, gathering, and transportation systems. IL-1422 contains additional chemistries formulated for systems with active underdeposit or MIC corrosion cells. The product will effectively treat the system while mitigating corrosion. IL-1422 can be applied continuously and is most often batched in front of

scheduled maintenance pigging.

Chemlogic IL-1500 is a concentrated pipeline cleaning compound. The product is a liquid, organic, surface-active chemical for removal and dispersion of paraffin, asphaltene, maltene, and a multitude of organic and inorganic debris deposits. The unique compound is postreaction admixed with debris removal surfactants and co-solvent penetrants. This oil soluble formulation is effective in removing and preventing redeposition of solids downstream in pipeline and separation equipment during cleaning and pigging projects. IL-1500 can be admixed between 25 – 50% with diesel, kerosene, aromatic solvent, or with a bio-renewable solvent for outstanding cleaning results. The product can be continuously injected into line days before the first cleaning pig run to help penetrate and remove debris quickly while pigging.

Chemlogic IL-1520 is a concentrated pipeline cleaning compound designed while working on multiple debris samples that contained high levels of asphaltenes and paraffin. Like IL-1500, the product is a liquid, organic, surface-active chemical chosen for its extreme penetration and removal of paraffin, asphaltene, maltene, and a multitude of organic and inorganic debris deposits. IL-1520 is an oil soluble, water dispersible, formulation that can be admixed at a rate of 25 – 50% with kerosene, diesel, aromatic solvent, or a bio-renewable solvent for effective removal and prevention of redeposition of debris further downstream in pipeline and separation equipment.

Chemlogic IL-1522 was designed while testing on a specific debris sample. Chemlogic has the capabilities to formulate site-specific compounds and ship those in 12 – 48 hours turnaround time. IL-1522 is formulated as a concentrated pipeline cleaning compound that has been successfully used to clean numerous lines that contain iron sulfide, iron contaminants, corrosion by-product, and high levels of salt crystalline formation. The product can be admixed at a rate of 25 – 50% with kerosene, diesel, aromatic solvent, or a biorenewable solvent for effective removal and prevention of redeposition of debris further downstream in pipeline and separation equipment.

Chemlogic IL-1525 was designed site specific, but has been found to work well on numerous debris samples and in systems contaminated with iron sulfide and various organic and inorganic debris. As mentioned above, Chemlogic has the capabilities to formulate new chemistries on a site-specific basis and have the unique compound onsite in 12 – 48 hours turnaround time. The laboratory will provide technical data verifying results after screening existing chemistries through rigid testing standards that deliver results. FeSGo 325 can be admixed at a rate of 25 – 50% with kerosene, diesel, aromatic solvent, or a biorenewable

solvent for effective removal and prevention of redeposition of debris further downstream in pipeline and separation equipment.

Chemlogic IL-1824 is yet another compound developed site specific and now found to perform outstanding on several problematic systems. The product contains proprietary dispersants and polymers that help suspend and sweep solids allowing thorough removal in fewer pig runs. The product was formulated with sand, clay, and silt suspending agents, along with iron sulfide and inorganic debris dissolution compounds. The product is to be applied neat but can be followed by other chemistries as recommended by Chemlogic’s technical personnel.

Chemlogic IL-1833 is an outstanding paraffin and asphaltene dispersant designed for the removal and dispersion of wax and asphalt deposits in production systems, gathering lines, and transportation pipelines.

Chemlogic IL-1900 is a leading-edge technology designed to disperse and inhibit salt and halite scale and debris in pipelines, gathering systems, waterfloods, production wells, and saltwater disposal systems. The product can be used in batch treatments to increase salt carrying capacity of connate or injected fluids utilized in pigging runs. IL-1900 was designed to be injected continuously into systems to prevent the formation of salt scales due to solubility issues.

Chemlogic IL-1901 is also a leading-edge technology designed to disperse and inhibit salt and halite scale and debris in pipelines, gathering systems, waterfloods, production wells, and saltwater disposal systems. The product was designed for batch treatments to increase salt carrying capacity of connate or injected fluids utilized in pigging runs. IL-1901 was formulated to be batched treated in front of pigging runs to remove existing salt scale debris.

DehySolv™ 100 Chemlogic DehySolv™ 100 is a novel dehydration humectant that is based on chemical absorption and physical laws that support the unique composition of polyhydric alcohols, diols, triol, and associated glycols which absorb water rather than mix with water. The compound absorbs up to 100% of its weight in water leaving surfaces water break-free and dry. Unlike miscible methanol, polyhydric alcohol absorb water in the gas stream, as well as the free water standing in the line. There is no serial dilution of water. When the chemistry is injected and pigged through the line, the dense solution is easily separated leaving pipeline contract gas due to its desiccating properties. In contrast, the low flash point compound commonly used, methanol, remains miscible in the water and passes easily in the vapor phase without being desiccated and dried.

DehySolv™ 102-CI Like DehySolv™ 100, DehySolv™ 102-CI is a novel dehydration humectant that is based on

chemical absorption. The compound was designed with a pipeline corrosion inhibitor to treat the internal pipe wall and leave a protection film to mitigate corrosion. DehySolv™ 102-CI can be used to dry hydrostatically tested lines, while leaving a molecular inhibition film that is persistent and long-lasting (depending on pipeline flow and contents).

Chemlogic IL-1700 is the premier gas pipeline corrosion inhibition compound designed to be applied continuously into gathering and transportation systems at the rate of one to two pints per MMSCFG. Field, laboratory, monitoring tests indicate IL-1700 provides over 98% protection in the most severe corrosion environments. The compound is a three-phase chemistry that will treat well in the condensate, water, and gas phases for complete pipe wall protection.

Chemlogic IL-1705 is an outstanding pipeline corrosion inhibitor designed for ongoing water intrusion issues and/or wet gas gathering. The compound has a proven history of delivering results in both oil and gas pipeline systems. The product can be injected continuously but is often batch treated in front of routine maintenance pigging runs to protect systems. Coupons utilized for monitoring efficacy will easily indicate performance that exceeds 98% protection.

Chemlogic IL-1915 is a unique formulation of phosphonates that will prevent inorganic carbonate and sulfate scale problems. The product is injected continuously at the rate of 20 – 45 ppm based on the water content in gathering or production systems. NACE loop scale tests indicate IL-1915 will effectively yield over 99% inhibition on most every inorganic scale found in the energy industry. Field results with ongoing monitoring of efficacy with scale coupons will indicate the effectiveness of this outstanding inhibitor.

IL-1930 is a unique formulation of polymeric scale inhibitor compounds that will prevent or mitigate ‘tough to treat’ inorganic scales including silicates. The product is injected continuously at the rate of 20 – 45 ppm based on the water content in gathering or production systems. NACE loop scale tests indicate ScaleGo 530 will effectively yield over 95% inhibition on most difficult inorganic scale found in the energy industry. Field results with ongoing monitoring of efficacy with scale coupons will indicate the effectiveness of this outstanding inhibitor.

Hydrogen Sulfide (H2S) is a common impurity found in oilfield waters and natural gas. Operating problems caused by H2S can include severe corrosion and fouling, injection well plugging with iron sulfides and safety problems related to H2S gases. Most pipeline companies require sales gas to be substantially free of H2S. Chemlogic IL-1955 quickly and effectively removes H2S without creating solids or other operating problems. For H2S removal from production waters, IL-1955 is applied at the rate of 100 ppm for every 5 ppm of dissolved H2S present in the water. For removal of H2S from natural gas, IL-1955 can be injected into the gas stream at the wellhead or contacted with the gas in a contactor tower. For this application the following relationship can be used: Lbs. of IL-1955 Required per Day = ppm H2S in gas x MMCF/day x 0.56.

Chemlogic IL-2775 is a polysaccharide gelling agent for pigging chemical sweeps or maintenance in unpiggable lines. IL-2775 is to be admixed before being injected into the pipeline. The compound is supplied as a slurry for ease of mixing. The chemistry is easily dissolved by the addition of time released gel breakers preset to deliver a clean line with easeof separation.

Chemlogic IL-2780 is also a polysaccharide gelling agent for pigging chemical sweeps in unpiggable lines. The compound varies from IL-2775 by its compositional makeup. Each gelling agent is designed for the conditions dictated by the line size and debris present. IL- 2780 is to be admixed before being injected into the pipeline. The compound is supplied as a slurry for ease of mixing. The chemistry is easily dissolved by the addition of time released gel breakers preset to deliver a clean line with ease of separation.

Chemlogic IL-1810 is an anti-foam/defoaming agent for pipeline cleaning and pigging programs. The product can be injected continuously to break down or prevent foam issues throughout the pigging and cleaning service. IL-1810 has proven very effective in Ethane transportation line cleaning projects. The product is often batch treated to break down foam quickly and only small amounts are required for effective defoaming.

IL-1815 Chemlogic IL-1815 is an outstanding anti-foam/defoaming agent for energy systems. The product is normally injected into production wellheads, gathering systems, and pipelines for quick and effective breakdown of troublesome foam problems. The injection rate is normally 30 – 90 ppm depending on the severity of the foam problem.

Hydra-Hib™ 630 Avoidance of hydrate formation is preferable to removal of existing hydrates from an economical view and safety concerns. To achieve this, the hydrate formation process can be influenced on several points: (a) dehydration of the gas before transport, (b) controlling of pressure and temperature during the transport, (c) use of thermodynamic hydrate inhibitors, THI (methanol is the most common), (c) use of kinetic hydrate inhibitors, KHI, (d) use of antiagglomerate chemistry, AA, (e) use of novel, combinatorial formulations of THI, KHI, and AA modifiers. Hydra-Hib™ 630 is a combinatorial thermodynamic, kinetic, and anti-agglomerate hydrate distorter for low to high chloride brines (up to 75,000 ppm chlorides). When compared to methanol, which generally takes up to 30% by weight of the water present in a system,

Hydra-Hib™ 630 requires less than 10% of the amount of methanol normally used. And, most importantly, Hydra-Hib™ 630 works when methanol or glycol often fail to prevent hydrate formation…even at the highest rates possible. Hydra-Hib™ 630 will lower hydrate inhibition cost by 50 – 90% while improving gas throughput.

Copyright © 2023 Chemlogic - All Rights Reserved.